Seamless rolled rings gives your forging the best strength, fatigue resistance, and freedom from inclusions.

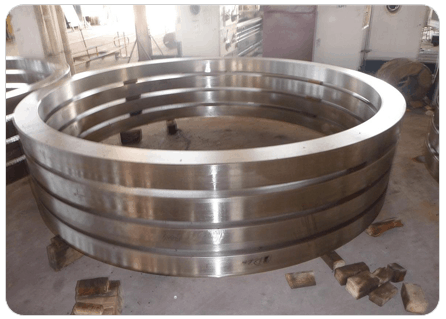

At Rickard Metals, we create shapes that vary in size, from flat washers to steel parts that are tall and cylindrical. Additionally, our seamless rolled rings can be delivered in both rough machined and finished machined state.

We manufacture a variety of rolled ring forgings that include:

Advantages of Seamless Rolled Rings

As mentioned above, seamless rolled rings imbue your forging with improved strength, fatigue resistance, and freedom from inclusions. Contoured rolled ring forgings or near net shape rolled rings offer not only a technical advantage but often also provide a cost advantage, as the forging process yields an end product that requires fewer machining operations, reduced weight and lower costs for raw materials.

Common Applications

Ring rolled forgings are used for flanges or gear blanks and can be rough machined or fully machined. As seamless rolled rings are a smooth product with concentric and tight tolerances, they often form key parts in jet engines, jet turbines, helicopter gearboxes, paper mills, windmills, and other extreme environments.

Ring Rolling Process

The process for creating seamless rolled ring forgings begins with punching a hole in a thick or round piece of billet (generally steel). The piece is then heated, rolled and squeezed into a ring. The ring rolling process orients the grain flow circumferentially providing greater resistance to fatigue and impact.

Why Seamless Rolled Rings by Rickard Metals

Rickard Metals has 25+ years of experience creating ring rolled forging products for the aerospace and other industries. Our rolled rings are created from the highest quality alloys and are produced to your custom measurements and sizes.