Ti-6Al-4V ELI Titanium alloy (also known as Ti 6-4 ELI and Grade 23) is the extra low interstitial variant of Ti 6AL-4V, allowing it for common use in the biomedical space. The combination of low weight, durability, and corrosion resistance make 6Al-4V ELI the perfect metal for medical devices and implants. Ti 6Al-4V ELI is mainly titanium based, with aluminum and vanadium being the other major chemical properties. Standard specifications for Grade 23 include AMS 4907, AMS 4930, Mil-T 9047 and more.

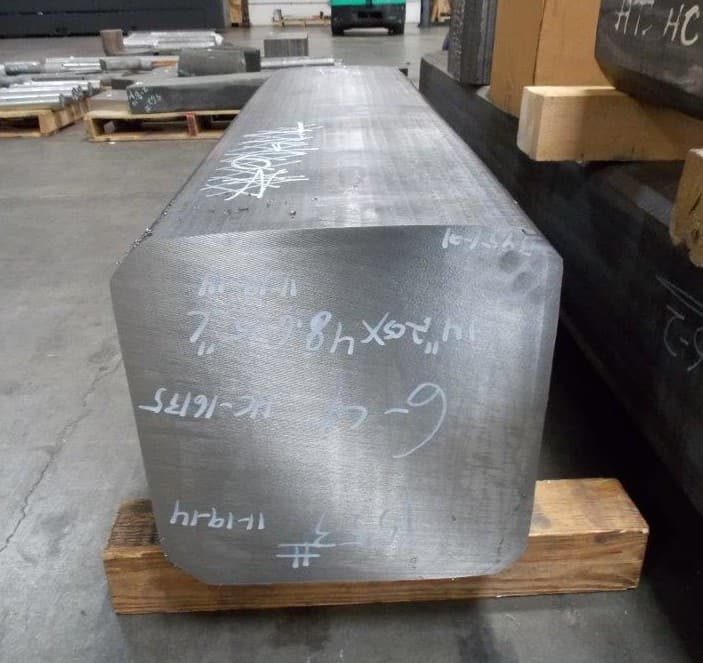

At Rickard Specialty Metals, we have 25+ years of experience supplying Ti 6-4 ELI forgings and many other product forms to your custom measurements and shapes. Our forging process includes open die forgings, ring rolling and more. See below for a list of the common Ti 6Al-4V ELI forged shapes and product forms we offer.

NOMINAL COMPOSITION

- Al 5.5 – 6.5

- V 3.5 – 4.5

- Fe .25 max

- O .13 max

- C .08 max

- N .03 max

- H .0125 max

- Y .005 max

- Ti Balance

- Remainder Each .1 max

- Remainder Total .4 max

STANDARD SPECIFICATIONS

- AMS 4907

- AMS 4930

- AMS 4931

- AMS 4956

- AMS 6932

- ASTM B 348

- ASTM F 136

- MIL-T 9047

FORGINGS

- Ti-6AL-4V ELI Round Bar

- Ti-6AL-4V ELI Flat Bar

- Ti-6AL-4V ELI Rectangular Bar

- Ti-6AL-4V ELI Rolled Rings

- Ti-6AL-4V ELI Forged Rings

- Ti-6AL-4V ELI Disc

OTHER PRODUCT FORMS

- Ti-6AL-4V ELI Sheet

- Ti-6AL-4V ELI Plate

- Ti-6AL-4V ELI Extrusion

- Ti-6AL-4V ELI Extrusion angles

- Ti-6AL-4V ELI Billet

- Ti-6AL-4V ELI Ingot

- Ti-6AL-4V ELI Machined Parts

Titanium 6-4 ELI Additional Information:

Physical Properties

Hardness: HRC 39 max, typical HRC 32-34.

Density: 0.161 lbs/cubic inch

Modulus of Elasticity: 16.3 msi

Coefficient of Expansion: 5.11 microinch/inch/degree F from RT to 600F

Machining

Ti 6al-4v ELI has a machining rating of is 22% (based on AISI AISI B1112). It is recommended to use low cutting speeds, heavy feed rates and copious amounts of cutting fluid. Chlorinated cutting fluids should be avoided to prevent contamination.

Welding

Ti 6Al-4V ELI has good weldability and improved over the basic grade ti-6al-4v titanium. This gain in welding, however, is at the expense of tensile/yield strength (see below). One should always use intert gas shielding and it is additionally recommended to perform post weld thermal processing. When performing fusion welding on 6-4ELI titanium, we recommend using a weld filler.

Forming

Ti 6-4 ELI provides slightly better forming characteristics and enhanced ductility over the regular grade Ti 6al-4v. Additionally, low temperature ductility is improved and one of primary reasons for selecting this grade. Overall, however, formability is still difficult for titanium 6-4 ELI.

Corrosion Resistance

Corrosion resistance for Titanium 6-4 ELI is generally excellent. Sometimes the alloy is susceptible to hot salt stress corrosion cracking. This risk can be minimized, however, with proper processing.

Heat Treatment

Ti-6Al-4V ELI displays limited section size hardenability, thus heat treatment is most commonly used in the annealed condition (various treatments below). Greater tensile properties, however, can be obtained by solution heat treatment followed by aging. While strength is gained from this, it is, however, at the expense of fracture toughness.

When annealing 6-4 Titanium ELI, Mill anneal (MA) is the general purpose anneal used. This is common for all mill products. One should be aware that it may not be a full anneal, however, and there may be traces of hot, cold or warm working in heavily worked products such as sheet. Duplex anneal and triplex anneal can also be used on for improved creep resistance and recrystallization anneal (RA) and beta anneal (BA) are used to improve fracture toughness. Lastly, Beta annealing should be done above the beta transus temperature.

When performing precipitation hardening, solution treatment and aging (STA) can result in a wide range of strength levels and ductility, depending on the STA cycle and the section size. Additionally, solution treatment and overaging (STOA) can result in some increase in strength, with satisfactory toughness and dimensional stability.

Ti 6-4 ELI Mechanical Properties for AMS4930

MINIMUM TENSILE VALUES, INCH/POUND UNITS

| Nominal Diameter of Distance Between Parallel Sides (Inches) | Tensile Strength ksi |

Yield Strength at 0.2% Offset ksi |

Elongation in 4D % Long. |

Elongation in 4D % L.T. |

Elongation in 4D % S.T. |

Reduction of Area % Long. |

Reduction of Area % L.T. |

Reduction of Area % S.T. |

| Up to 1.500, incl | 125 | 115 | 10 | 10 | — | 25 | 20 | — |

| Over 1.500 to 2.000, incl | 120 | 110 | 10 | 10 | — | 20 | 15 | — |

| Over 2.000 to 2.500, incl | 120 | 110 | 8 | 8 | — | 15 | 15 | — |

| Over 2.500 to 4.000, incl | 120 | 110 | 8 | 8 | 8 | 15 | 15 | 15 |

MINIMUM TENSILE VALUES, SI UNITS

| Nominal Diameter of Distance Between Parallel Sides (Millimeters) | Tensile Strength MPa |

Yield Strength at 0.2% Offset MPa |

Elongation in 4D % Long. |

Elongation in 4D % L.T. |

Elongation in 4D % S.T. |

Reduction of Area % Long. |

Reduction of Area % L.T. |

Reduction of Area % S.T. |

| Up to 38.10, incl | 862 | 793 | 10 | 10 | — | 25 | 20 | — |

| Over 38.10 to 50.80, incl | 827 | 758 | 10 | 10 | — | 20 | 15 | — |

| Over 50.8 to 63.50, incl | 827 | 758 | 8 | 8 | — | 15 | 15 | — |

| Over 63.50 to 101.60, incl | 827 | 758 | 8 | 8 | 8 | 15 | 15 | 15 |